Welcome to Jouhsen Bundgens!

Do you process thin wire or tube? Then you have come to the right place. Jouhsen Bundgens is the world’s leading specialist for rotary straightening. For over 150 years, we have been building wire processing machines for markets in Europe, America and Asia.

From cutting and grinding to cold-forming and machining, we develop the steps needed to process wire and thin tubing measuring 0.02 mm to 16 mm in diameter, all tailored precisely to the challenges you face. If you wish, we can even integrate these processes into an automated concept. With over a century and a half of processing expertise, Jouhsen Bundgens also offers special engineering, feed and handling systems.

Our range of systems and machinery has grown over time to include filling systems for infusion bags and bottles with volumes ranging from 20 to 1,000 ml for the demanding requirements of the pharmaceutical industry.

Everything that we do here at Jouhsen Bundgens boils down to a simple formula:

Speed + precision = efficiency – find out for yourself.

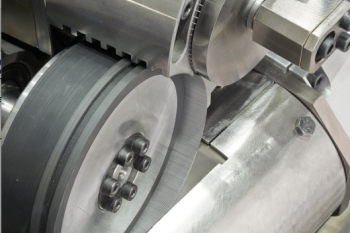

Excellent surfaces

When excellent surfaces are required, straightening requires comprehensive process know-how. Find out more.

We can´t wait to meeting you!

In Düsseldorf – at stand G51 in hall 11, we will show you what rotary straightening is capable of.

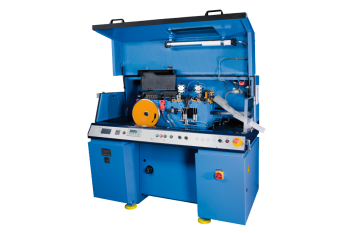

PrecisionCut UD0

Our smallest straightening and cutting machine processes short and long sections of the thinnest wire. Would you like to get to know it?

Efficient point grinding systems

PrecisionGrind PG3 and PG11 for grinding short needle sections.