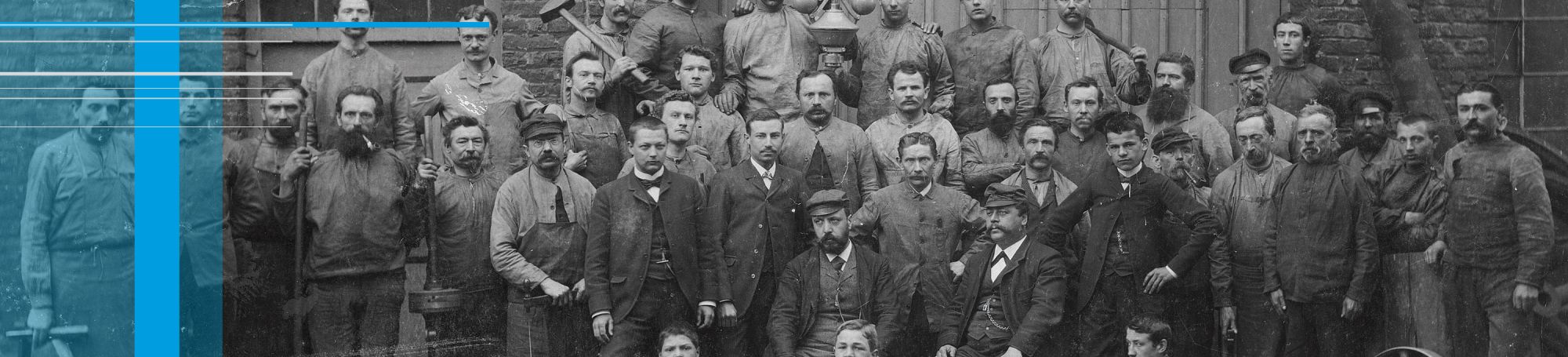

1864

Foundation of F.W. Bundgens

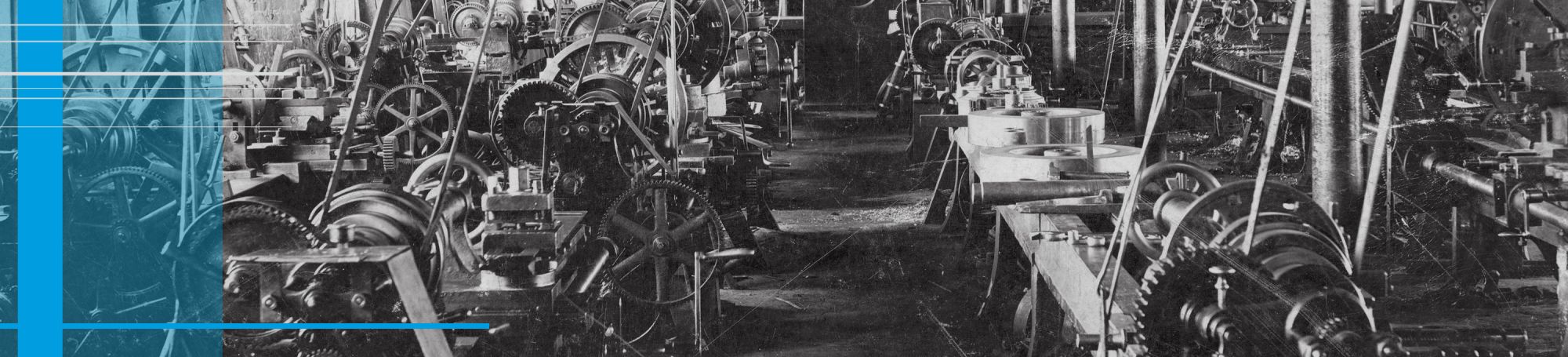

The company initially specializes in producing machines for the textiles and needle industry. It later goes on to develop technically advanced wire straightening and cutting machines, as well as grinding machines and further systems for wire processing.