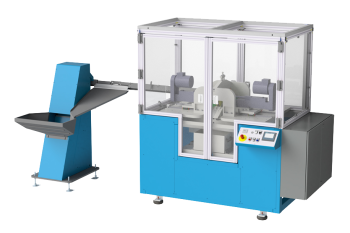

PrecisionShape MJE2

The PrecisionShape MJE2 stands out for its very high speed. Just like the MJE, it far exceeds that of conventional lathes. A lever system feeds the wire into the machine with great precision and at a very high speed. The parts are cut by a bushing-on-bushing cutting unit, after which they are conveyed to a transport plate.

The PrecisionShape MJE2 firmly holds the parts at a very short distance in the machining position. Hence, the machine achieves a very high machining accuracy. The transport plate employs a positive stop to ensure that length tolerances of the parts do not impact on end machining. Up to four rotating tools can be employed (two on each side).

With the PrecisionShape MJE2 you can achieve an output of up to 200 units per minute. For wire diameters of up to 6 mm and lengths of up to 250 mm. The machine consists of two independent components: a straightening and cutting machine and an end machining unit.

Technical features

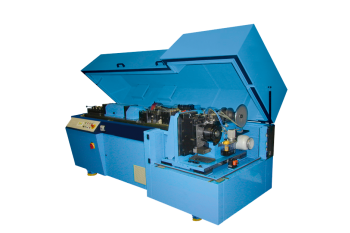

Straightening and cutting machine

1. Zero-vibration design

Vibration-free design with precision-ground, exchangeable linear guides for tool fitting. The infeed, cutting and machining systems are cam-driven with a split cam design.

3. Can be used separately

The straightening and cutting machine can also be used without the end machining unit.

2. Excellent straightening results

Two infeed slides for an optimum straightening result especially for longer parts.

End machining unit

1. High precision

High-precision machining of cut-off wire shafts enabling a wide range of end styles.

3. High flexibility

Maximum performance and high degree of flexibility thanks to CNC motion sequences. Accurate end shapes irrespective of part length tolerance due to alignment of the parts in the machining position.

2. Short fitting times

Length adjustment is CNC controlled via a touch panel, enabling fast changeover. Adjustment of spindle RPM and infeed speed via touch panel with programmable PLC. 2 machining stations on each side of the cutting unit are possible.

4. Enclosed housing

The closed machine housing keeps noise levels low and is easily accessible on all sides. Machine drive, electronics and central lubrication are integrated in the machine housing.

Our machines for end machining

PrecisionShape MJE

The PrecisionShape MJE from Jouhsen Bundgens processes wire ends faster than any conventional machine and with high precision.

PrecisionShape EB9

The PrecisionShape EB9 is perfect for finishing cut and straightened parts. It is cost effective and easy to use and service.

PrecisionShape UER

The PrecisionShape UER is the machine series for the production of pins with rolled ends.

Do you want more information about the PrecisionShape MJE2?

Get in touch, we will be happy to help you.